The importance of EMI power line filter installation

Even if a suitable filter is selected, improper installation will still destroy the attenuation characteristics of the filter. Good results can only be obtained if the filter is properly installed.

We has been researching in the field of EMC for several years and has customized many EMI power filters for customers. We have extensive experience in installation and commissioning.

1) The filter is best installed at the entrance and exit of the interference source, and the filter housing and the interference source housing should be well overlapped.

2) The input and output lines of the filter must be separated to prevent line coupling between the input and output ends and reduce the attenuation characteristics of the filter. Products usually use partitions or chassis to fix filters. If isolation methods cannot be implemented, the shielded leads must be reliable.

3) The capacitor wires in the filter should be as short as possible to prevent the inductive reactance and capacitive reactance from forming resonance at a certain frequency. The capacitors should be installed at right angles to other capacitors and components to avoid mutual influence (near field effect).

4) There is a large short-circuit current on the ground line of the filter, which can radiate strong electromagnetic interference. Therefore, the suppression components of the filter must be well shielded.

- Each wire welded to the same socket must be filtered, otherwise the attenuation characteristics of the filter will be completely lost.

Let’s analyze the importance of filter installation:

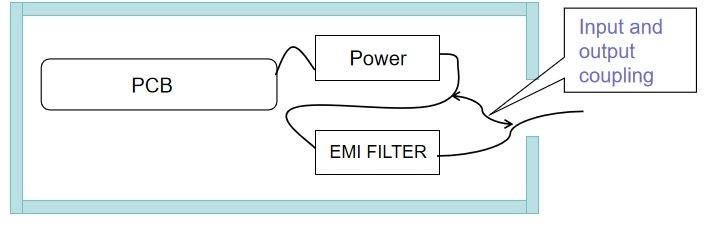

The method of installing the filter as shown in Figure 1, Figure 2, and Figure 3 below is problematic. The essence of the problem is that there is obvious electromagnetic coupling path crosstalk between the filter’s input cable, its output and the internal PCB circuit. In this way, the EMI signal existing at one end of the filter will escape the restriction of the filter and be directly coupled to the other end of the filter without being attenuated by the filter.

Figure 1 Installation diagram of filter input line problem

In addition, the filters in the picture are all installed inside the equipment shield. EMI signals on the internal circuits and components of the equipment will be directly coupled to the outside of the equipment due to electromagnetic coupling such as crosstalk, which generates EMI signals on the power supply connection line of the filter. , causing the device’s shielding to lose its ability to suppress EMI radiation generated by internal components and circuits. At the same time, if there is a common-mode interference signal on the filter input cable, it will also couple across the filter to the components and circuits inside the device, thus destroying the filter and shielding effects.

When installing filters or placing filter circuits in electronic equipment or systems, be aware that when bundling equipment cables, the cables at the input end of the filter and the cables at the output end of the filter cannot be bundled together. When wiring the PCB, the signal at the input end of the filter and the signal at the output end of the filter cannot be arranged together. If they are arranged together, the electromagnetic coupling between the input/output ends of the filter will be aggravated, causing crosstalk. This will destroy the ability of the filter and equipment shielding to suppress interference signals.

Another important point is that there is a good low-impedance electrical connection between the filter housing or the common-mode filter Y capacitor in the filter circuit and the system/structure ground. That is to say, the grounding of the filter must be handled well. It is best not to install the filter on an insulating object as shown in Figure 3. It should be installed on a metal shell with good contact and avoid using long ground wires. Because an excessively long ground wire means a significant increase in ground inductance and resistance, which will seriously damage the filter’s common-mode suppression capability. A better method is to use metal screws and star-shaped spring washers to securely fasten the filter shield to the chassis at the power inlet of the equipment.

The correct installation of the filter is shown in Figure 4. The characteristic of this installation method is to use the shielding of the equipment to effectively isolate the input end and output end of the power filter. The electromagnetic coupling, that is, crosstalk problem, is controlled to a minimum level.

As shown in Figure 1, the connection line between the filter and the power port is too long. This is a common mistake for two reasons:

1) For situations of resisting external interference: The external interference transmitted into the device along the power line has not been filtered yet, and has already interfered with the circuit board through spatial coupling, causing sensitivity problems.

2) In the case of product internal interference emissions (including conducted emissions and radiated emissions): the interference generated on the circuit board can be directly coupled to the outside of the filter and conducted to the outside of the product casing, causing excessive electromagnetic emissions (including conducted and radiated emissions). ).

Why this error easily occurs? In addition to the fact that design engineers treat the filter as an ordinary circuit network, there is another objective reason that is prone to problems: the power cord input end of the equipment is usually on the rear panel of the product or equipment, and Display lights and switches are on the front panel of products and equipment, so after the power cord enters the product or equipment from the rear panel, it is often first connected to the display lights and switches on the front panel, and then connected to the filter.

Figure 2 Installation diagram of filter input and output line issues

As shown in Figure 2, the input and output lines of the filter are too close. The reason for this error is also the neglect of the spatial coupling of high-frequency electromagnetic interference. When arranging the internal connecting lines of products and equipment, for the sake of appearance, the input and output ends of the filter are tied together. As a result, there is a large distributed capacitance between the input line and the output line, forming a coupling path, so that the electromagnetic interference energy will actually When the filter is bypassed, especially in the high frequency band, the filtering effect becomes worse.

Note: When dealing with electromagnetic compatibility issues, high-frequency electromagnetic interference will propagate and couple through space, and may not propagate according to the designed ideal circuit model. Therefore, when designing the product casing and structure, try to keep the power port as far away from the signal port as possible.

Figure 3 Installation diagram of filter grounding problem

As shown in Figure 3, if the filter is grounded through a thin wire, the high-frequency effect will become worse. There is a grounding terminal on the filter housing, which invisibly reminds the user that the filter needs to be grounded. Therefore, in actual projects, you will see that the ground terminal of the filter is connected to a ground wire. Note: Improper connection of this wire will affect the performance of the filter.

1) Connection method of the ground terminal of the filter: In the basic circuit of the power line filter, one end of the common mode filter capacitor is connected to the filtered conductor (L line and N line), and the other end is connected to the ground. For the filter, the ground is the filter housing, and the ground terminal on the filter is the filter housing. From the principle of the filter, the ground terminal of the common mode filter capacitor should be connected to the shielded chassis or a large metal plate. This ground terminal is what allows you to connect the filter to the chassis or large metal plate.

2) Application issues of ground terminals in practice: When designing Y capacitors, the issue of leakage current must first be considered. In filters, even short leads will have a great impact on the bypass effect of the capacitor, so When designing an electromagnetic interference filter, do everything possible to shorten the capacitor leads (even use three-terminal capacitors or feedthrough capacitors). The filter is grounded through this ground terminal, which is equivalent to extending the lead length of the common mode filter capacitor.

The actual situation shows that the length of these ground wires has long exceeded the tolerable level. Therefore, these ground terminals are generally useless (unless a very short, thick ground wire is used). On the contrary, and with bad effect, the wrong thing to do is to run a long wire through it to ground.

3) Correct grounding method: The metal shell of the filter must be attached to the conductive surface of the metal chassis over a large area.

When the filter is grounded as shown in Figure 3 (there is no conductive contact between the filter metal casing and the chassis, only a thin wire is connected), the common-mode filtering effect of the filter will be particularly poor at a certain frequency. , almost close to the effect without common mode filter capacitors.

Figure 4 Diagram of correct installation of filter

The recommended installation method of the filter is shown in Figure 4. The direct connection of the filter to the ground should be as short as possible, and the input and output lines should be isolated.

The input and output of the filter can be installed directly on the metal plate on both sides of the chassis to minimize contact impedance. The metal panel of the chassis is used to isolate the input and output of the filter to prevent high-frequency coupling. It is best to install an electromagnetic sealing gasket between the filter and the chassis panel (in some applications, the electromagnetic sealing gasket is necessary, otherwise leakage will occur in the contact gap). When using this installation method, the filtering effect of the filter mainly depends on the performance of the filter itself.

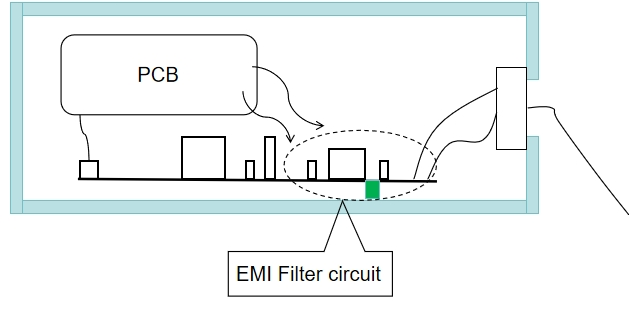

Figure 5 Schematic diagram of the filter on the PCB circuit board

As shown in Figure 5, in order to reduce costs for general-purpose products, the filter is directly mounted on the circuit board. This method has some benefits in terms of direct costs, but the actual cost-effectiveness ratio is not high. Because high-frequency interference will directly induce any part of the filter circuit, causing the filter to fail. Therefore, this method is often only suitable for situations where the interference frequency is very low.

If the filter circuit is designed on the PCB and the grounding is implemented by PCB printed lines, then the grounding of the common mode filter capacitor, that is, between the common mode filter capacitor and the metal shell or product grounding point, must be with an aspect ratio of less than 3 printed lines. For the grounding of the differential mode filter capacitor, that is, between the differential mode filter capacitor and the working ground pin of the interface chip, a printed line with an aspect ratio less than 3 must also be used. This is considered a good grounding in the EMC sense.

If this filtering method is used on the PCB circuit board, that is, a filter circuit is designed on the switching power supply, and there are still EMC problems, a remedy is to design a common mode filter device at the entrance of the power line. This Filter devices can only suppress common-mode interference.

In fact, the interference voltage induced from the space to the wires is in the form of common mode. The circuit can be composed of a common mode choke and two common mode filter capacitors to obtain a good filtering effect.

But be careful: the common mode Y capacitance here is added to the original one, which may cause the leakage current to exceed the standard.

This method of dividing the filter into two parts on the circuit board and at the port has a high cost-effectiveness ratio. This method can be considered in situations where cost control is not strict but interference suppression requirements are high.

Note: The most effective way to solve power line EMC problems is to install a power line filter at the power inlet. An important indicator for measuring filters is insertion loss. Bad filters and incorrect installation will not work as expected. To obtain the desired effect, not only the filter must meet the requirements, but also the installation method is important.

For the design of EMC, the design of the filter is very important for the common mode current, whether it is the common mode interference current injected into the interface or the common mode noise current of the internal circuit products.

1) For the common mode filter, it not only reduces the common mode current, but also

A capacitive common mode filter can also change the path of the common mode current.

2) For the differential mode filter, it cannot change the size of the common mode current nor the path of the common mode current, but it can convert the common mode current transmission due to the unbalanced transmission circuit into a differential mode interference signal and filter it out.